From The Classroom To The Workshop

Day 4 of the course and we were in the workshop tackling 1st stage disassembly and reassembly. First up were a Northern Diver and an Apeks DST, both diaphragm designs. The instructor took us through each step and then got us to do the same. The first one was a challenge but it worked well; no components were left over, it locked up correctly and there was no creep. The second one was easier, even with the differences between the two, but it too performed as expected.

In the afternoon it was on to an Apeks ATX200 2nd stage. It was challenging being the first time but not too much adjustment was needed to lever height or cracking pressure. BTW, the medium pressure in my 1st stage from this morning remained rock steady at 9.5 bar!

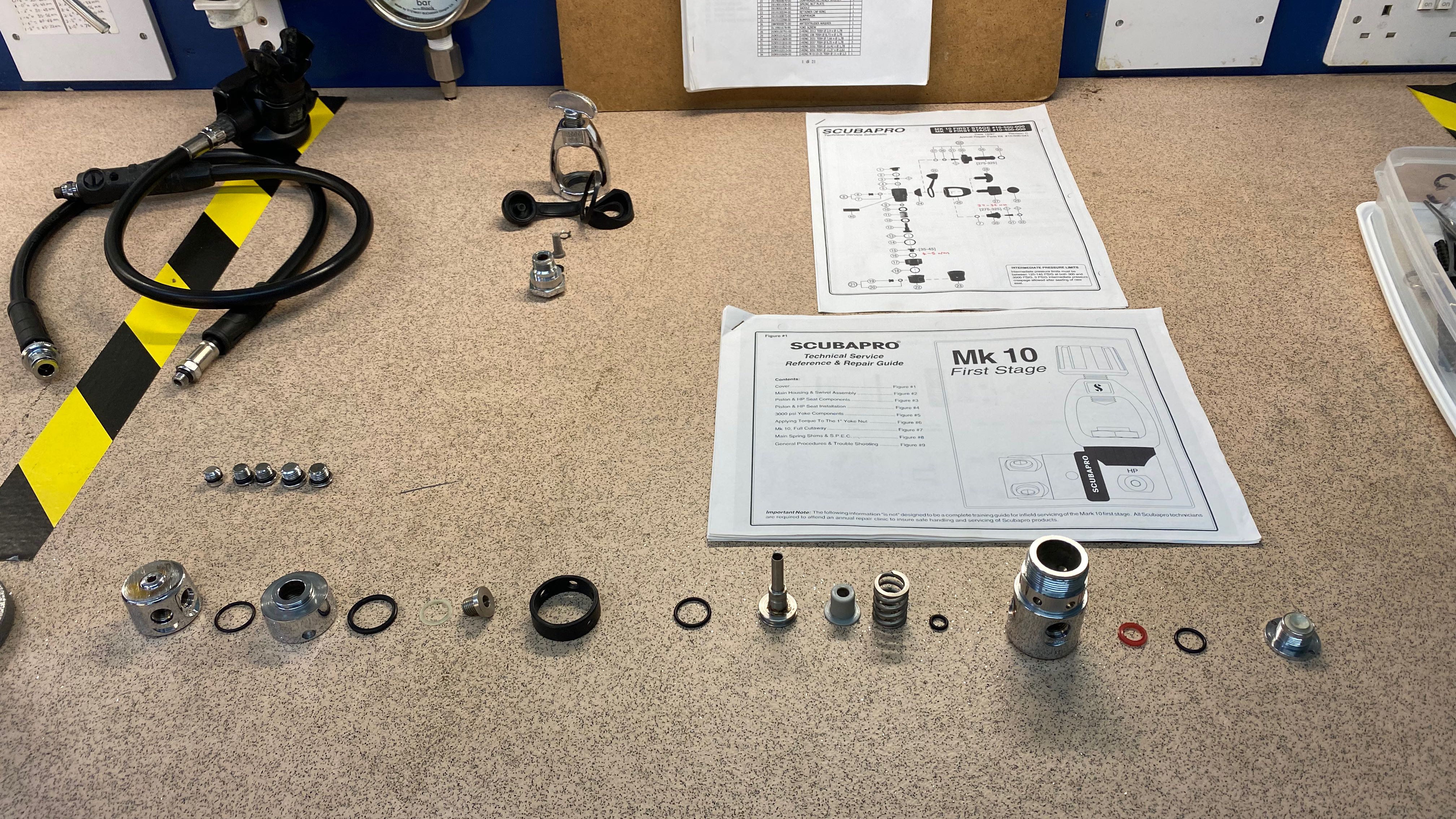

On day 5 the emphasis shifted to piston 1st stages and the teaching moved to a, “follow the manual and study the diagrams” approach. First up was a Coltri Sub C30 followed by a SCUBAPRO Mk 10, shown here half-way through the process:

Once one was disassembled we checked everything looked OK and then reassembled it. Both went fine in terms of lock-up and creeping

This workshop session ended with a SCUBAPRO R390 2nd stage. We were left to disassemble and reassemble on our own (obviously following the manual) and “judged” on the performance of the finished item. I was very pleased that mine only needed a minor adjustment (i.e. a couple of degrees on the inline adjuster) to meet the manufacturers specifications.